Nuts Peeling and Cooling Hazelnuts Peanuts

The Peelers are featured by a supporting frame whose dimension changes according to the client's needs. They are made of different overlapping circular stages, where the hot product (hazelnuts, peanuts, etc.) is constantly moved by a central rotating set of arms to get a uniform and complete cooling. The product crosses the peeler from top to bottom, passing through the separate stages in a programmed and temporised way by means of a trap door system with pneumatic cylinder.

The ambient air (or, on request, chilled air), passes through the product layer, cooling it. The skins are collected and decanted. At the end of the cycle, the final product is clean, intact and of high-quality level.

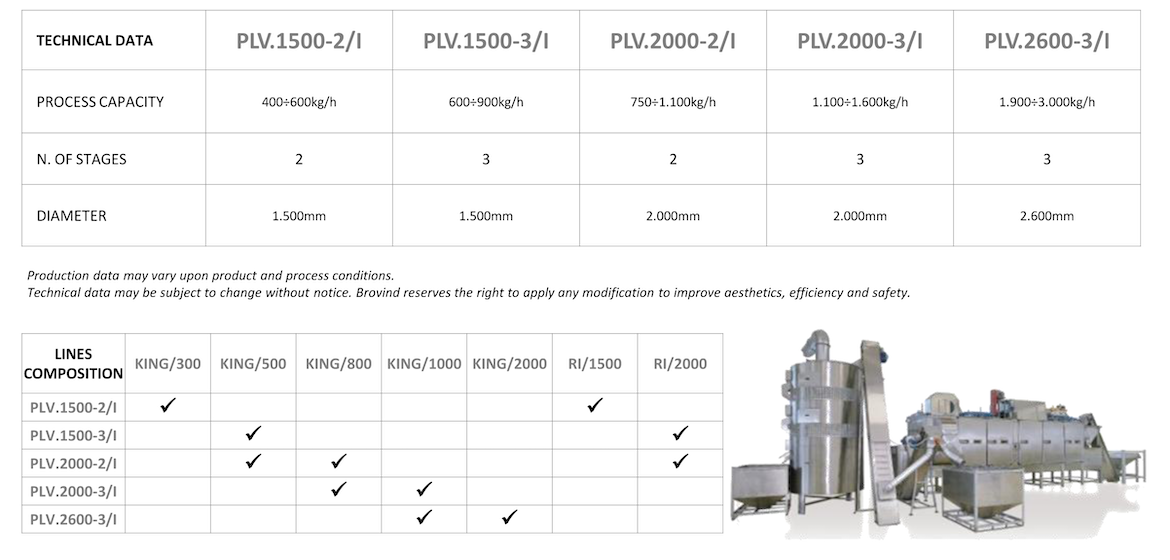

Brovind offers customized solutions to meet any customer’s needs.